Over three quarters of polyurethane global consumption is in the form of polyurethane foam with both flexible and rigid types of the foam being approximately equal in regard to market size. The foam product is frequently used behind other materials to create products. For example the flexible foam is placed behind upholstered polyester polyurethane fabric in commercial and domestic furniture to provide the soft cushion for you to sit on.

Polyester fabric has a number of different applications, and the finished products are used very often in our everyday lives. From your comfortable, cushioned office chair at work to the tire covers of your car, polyurethane foam technology is used everywhere. Advances in technology have allowed for a range of cutting technologies and post-treatment technologies, allowing specialists to craft the material into a range of shapes and to a variety of specifications. Due to its increasing flexibility, customization, and rigidity, this material finds its place in a number of industries and serves an almost unlimited number of purposes.

Vehicles

Polyester polyurethane fabric truly moves the world. Because its use allows for high-quality, lightweight parts, this material is found everywhere in the automotive and transportation industries. In addition to use in the obvious areas-seat cushioning in cars, boats, RVs, and more-it is also used to trim interior panels and line tire covers. Polyurethane can even be used in the vibration and harshness (NVH) coatings of many vehicles. These coatings are designed to moderate noise levels in the inside of the vehicle.

Upholstery and Bedding

Specialized foam fabrication allows specialists to craft unique shapes for upholstery cushions. High-density polyurethane is an ideal option for padding chairs and seats, and the relatively low cost and quick execution of this material are what make “egg crate” mattress toppers such a cost-effective option.

Footwear

Researchers have long been proponents of the use of polyester polyurethane fabric in running shoes. Because this material lessens the force of impact when running, long-term jogging enthusiasts take less damage to their ankles and knee joints. When it comes to foam fabrication, certain mixtures and densities can be used to craft running footwear for specific needs: some offer excellent cushioning for those with flat feet, while others are designed specifically for high-mileage road running.

Insulation

Spray foam insulation was developed in the 1940s for use by the military to insulate airplanes. Today, spray foam is used to help homeowners save money by lowering their utility bills. This fabric material expands when sprayed. Its dry, dense structure gives the added benefits of protecting against moisture and reducing sound transfer between rooms.

Packaging

Polyurethane foam is regularly used by the packaging industry to protect items and ensure the careful transportation of goods. Foam packaging is one of the most common forms of successful packaging. The polyurethane formulation enables the foam to be moulded to the shape of a product or item to get the best fit and protection possible. Many packaging manufacturers can provide bespoke packaging whereby the foam can be moulded to the shape of any item – no matter how odd! The introduction of antistatic foam and conductive foam demonstrates how technology has moved forward and the true diversity of polyurethane foam.

Regardless of where you live, work, or play, polyester polyurethane fabric foam is a part of your everyday life. It continues to be one of the most cost-effective manufactured products on the planet, and variations of this material are in more homes around the world than just about any other product.

Properties of Polyester Polyurethane Fabric

Polyester polyurethane fabric is a versatile material with a unique set of properties that make it suitable for a wide range of applications. Understanding these properties is essential for anyone considering the use of this fabric in their projects. Let’s dive into the key characteristics of polyester polyurethane fabric:

A. Composition and Manufacturing Process

Polyester polyurethane fabric is composed of two main components: polyester and polyurethane. Polyester provides the fabric with strength, durability, and stability. Polyurethane, on the other hand, enhances the fabric’s flexibility, stretch, and water-resistant properties. The manufacturing process involves combining these materials through a series of chemical reactions, resulting in a fabric that blends the best of both worlds.

B. Durability and Strength

One of the standout features of polyester polyurethane fabric is its durability and strength. Polyester fibers are known for their resilience and resistance to wear and tear. When combined with polyurethane, the fabric becomes even more robust, making it suitable for high-stress applications. Whether used in upholstery, outdoor gear, or industrial settings, this fabric can withstand the rigors of daily use.

C. Water Resistance

Polyester polyurethane fabric boasts excellent water-resistant properties. The polyurethane component of the fabric creates a protective barrier that repels moisture, preventing it from penetrating the fabric. This water resistance is especially valuable in applications like rain jackets, backpacks, and automotive interiors, where keeping dry is crucial.

D. Flexibility and Stretch

Flexibility and stretch are essential characteristics of polyester polyurethane fabric. The polyurethane component adds elasticity to the fabric, allowing it to stretch and conform to various shapes and movements. This makes it ideal for applications where flexibility is needed, such as in sportswear and upholstery.

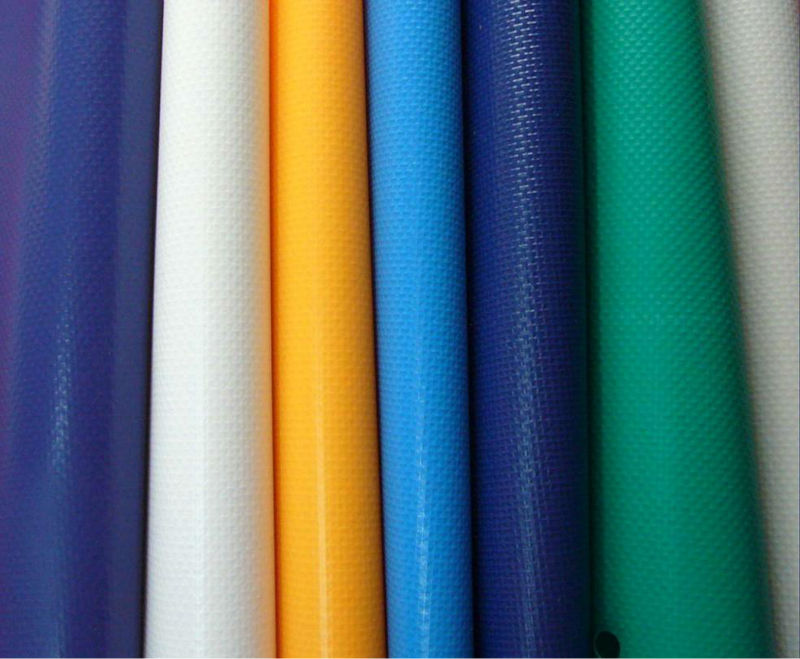

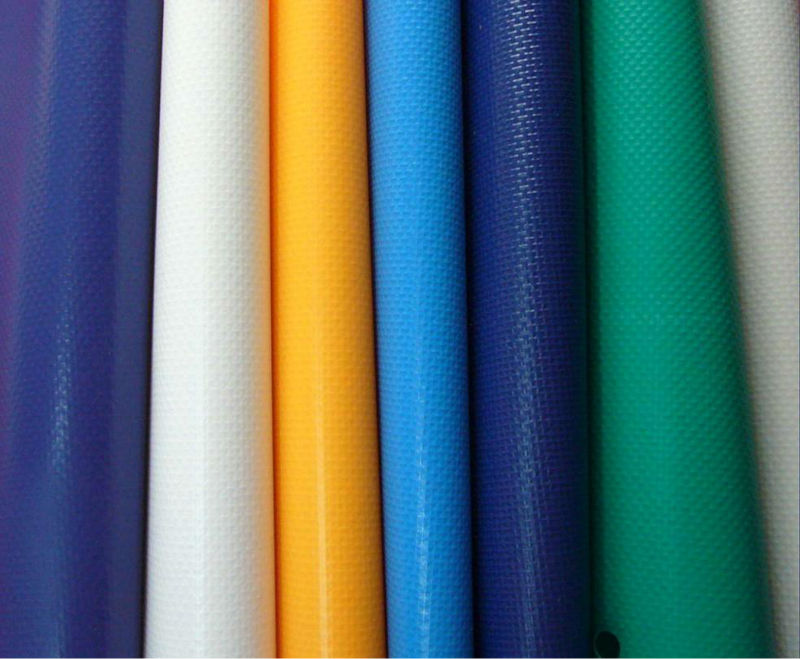

E. Color Retention

Polyester polyurethane fabric is known for its excellent color retention. The fabric can hold dyes exceptionally well, resulting in vibrant and long-lasting colors. This makes it a popular choice in fashion and upholstery, where maintaining the original appearance of the fabric is essential over time.

In summary, the properties of polyester polyurethane fabric, including its composition, durability, water resistance, flexibility, stretch, and color retention, make it a versatile and reliable choice for a wide range of applications. Whether you’re designing outdoor gear, upholstery, or fashion items, understanding these properties can help you make informed decisions about using polyester polyurethane fabric in your projects.